|

Zhengzhou Toone Mechanical Equipment Limited Company

|

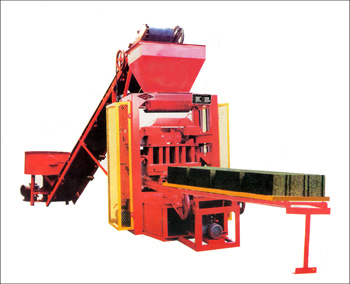

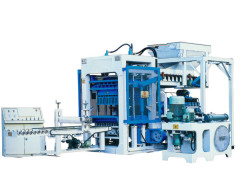

brick making machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Higher efficiency

2. Lower electrical-consumption

3. Energy-saving,low noise

4. Less occupying area&noise,etc

4-26 type block molding machine application:

The block forming machine suitable for the production of various specifications of the standard bricks, hollow block, brick and other concrete products.

4-26 type block molding machine characteristics:

The block forming machine for mechanical, hydraulic, computer automatic control / electronic integrated technical equipment, with high efficiency, reasonable design, compact structure, simple operation, easy maintenance features. Block molding machine mainly with hydraulic, mechanical subsidiary, vibration pressure to complete.

The production of block compressive strength over is 15Mpa (MPA), high density, frost resistance, impermeability, sound and heat insulation, excellent thermal insulation performance, dimension precision.

4-26 type block molding machine advantages:

1. Block molding machine in line with the the GB/T8533-1998 small block molding machine professional recommendation.

2. Block molding machine adopt electro-hydraulic integration technology, the equipment recycling process is consistent so that the product has high stability and low reject rate.

3. Automatic process select foreign advanced PLC ( programmable logic controller )Intelligent control system, equipped with intelligent control, data input, storage, touch screen, the ideal flexible man-machine interface. The automatic control system comprises advanced security logic to control operation interlock, and with remote control system.

4. By simply changing the mold, can quickly adjust production, the maximum meet the market demand, to allow the device to play the ultimate performance.

4-26 block molding machine specifications:

Total Power | 42 KW | |

Productivity | Standard bricks | 25000*2 blocks / shift |

bricks(390*190*190) | 4000*2 blocks / shift | |

Molding Cycle | 25 s | |

Total Weight | 11 T | |

Pallet Size | 850*540*40 mm | |

Dimension | 3000*1950*2400 mm | |

Executive Standard | GB/T8533-1998 | |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Cement Brick Making Machine

Concrete Brick Making Machine

Clay Brick Making Machine

Brick Making

Automatic Brick Making Machines

Brick Making Equipment

More>>

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35